| Brand | ROCKWILL |

| Model NO. | 12kV 24kV 36kV Maintenance-FreePure air/Nitrogen Insulated Ring Main Unit(RMU) |

| Rated voltage | 36kV |

| Rated normal current | 630A |

| Rated frequency | 50/60Hz |

| Series | REC |

Description:

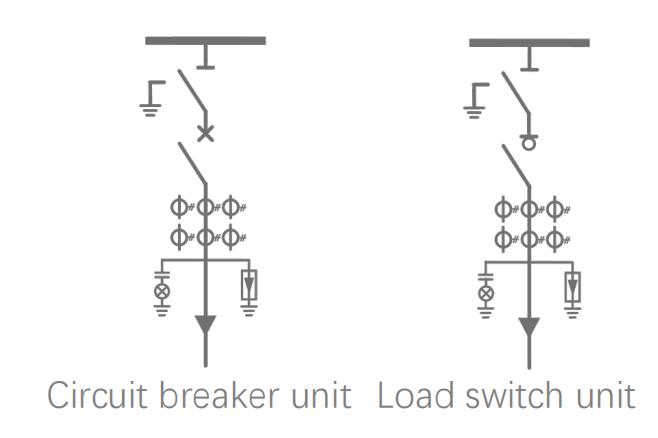

ROCKWILL® attaches great importance to product quality and manufacturing technology, and treats every step of product production with precision and meticulousness. Only insulation gas is used to comprehensively compare heating dry air, nitrogen, carbon dioxide, and pure air. Pure air synthesized with extremely low moisture content and high purity is selected as the preferred insulation gas to replace SF6. The core switch unit of the product adopts a brand new vacuum arc extinguishing chamber soft package casting process, combined with a carefully designed rotating three-position switch, with a simple and compact overall structure; The fully sealed gas box replaces SF6 with pure air, with a highly advantageous electric field distribution design, and the partial discharge of the entire cabinet is below 5pC; The salt spray resistance test of the operating mechanism of the zinc inlay alloy surface treatment process has exceeded 168 hours, and the longest service life can reach 30000 times.

Feature:

Pure air/Nitrogen insulated ring main unit

Environmentally friendly gas

Zero carbon emissions, zero waste

Intensive and meticulous producing, Seeking finer quality

Comply with IEC/ANSI standards

Provided customized manufacture

Whole solutions for design, assembly, test...

Accountable solution for safety and reliability

Wide range offering, easy business and convenient installation

Main technical parameters (three phase):

12kV

N |

Item |

Unit |

Data |

1 |

Rated maximum voltage |

kV |

12 |

2 |

Rated maximum current |

A |

630/1250 |

3 |

Rated frequency |

Hz |

50/60 |

4 |

Method of Arc Suppressing |

Vacuum |

|

5 |

Method of Insulation |

Pure air/Nitrogen |

|

6 |

Rated short circuit breaking current |

kA |

20/25 |

7 |

Rated peak value withstand current |

kA |

50/63 |

8 |

Rated 1min power frequency withstand voltage |

kV |

42 |

9 |

Rated lightning impulse voltage |

kV |

75 |

10 |

Operation sequence |

/ |

C-0.3-CO-180-CO |

12 |

Resistance loop |

μΩ |

≤140 |

13 |

Rated gas pressure (20℃ gauge) |

Mpa |

0.02 |

14 |

Minimum operating gas pressure |

Mpa |

0 |

15 |

Mechanical life - Circuit breaker |

N |

10000 |

Mechanical life - Load break switch |

N |

3000/6000 |

|

Mechanical life - Disconnector |

N |

3000/6000 |

|

Mechanical life - Earthing switch |

N |

3000/6000 |

|

16 |

Protection grade - Gas tank |

IP67 |

|

Protection grade - Shell |

IP4X |

||

17 |

Rated annual air leakage rate |

% |

0.01 |

24kV

N |

Item |

Unit |

Data |

1 |

Rated maximum voltage |

kV |

24 |

2 |

Rated maximum current |

A |

630/1250 |

3 |

Rated frequency |

Hz |

50/60 |

4 |

Method of Arc Suppressing |

Vacuum |

|

5 |

Method of Insulation |

Pure air/Nitrogen |

|

6 |

Rated short circuit breaking current |

kA |

20/25 |

7 |

Rated peak value withstand current |

kA |

50/63 |

8 |

Rated 1min power frequency withstand voltage |

kV |

42 |

9 |

Rated lightning impulse voltage |

kV |

75 |

10 |

Operation sequence |

/ |

C-0.3-CO-180-CO |

12 |

Resistance loop |

μΩ |

≤140 |

13 |

Rated gas pressure (20℃ gauge) |

Mpa |

0.02 |

14 |

Minimum operating gas pressure |

Mpa |

0 |

15 |

Mechanical life - Circuit breaker |

N |

10000 |

Mechanical life - Load break switch |

N |

3000/6000 |

|

Mechanical life - Disconnector |

N |

3000/6000 |

|

Mechanical life - Earthing switch |

N |

3000/6000 |

|

16 |

Protection grade - Gas tank |

IP67 |

|

Protection grade - Shell |

IP4X |

||

17 |

Rated annual air leakage rate |

% |

0.01 |

36kV

N |

Item |

Unit |

Data |

1 |

Rated maximum voltage |

kV |

36 |

2 |

Rated maximum current |

A |

630/1250 |

3 |

Rated frequency |

Hz |

50/60 |

4 |

Method of Arc Suppressing |

Vacuum |

|

5 |

Method of Insulation |

Pure air/Nitrogen |

|

6 |

Rated short circuit breaking current |

kA |

20/25 |

7 |

Rated peak value withstand current |

kA |

50/63 |

8 |

Rated 1min power frequency withstand voltage |

kV |

42 |

9 |

Rated lightning impulse voltage |

kV |

75 |

10 |

Operation sequence |

/ |

C-0.3-CO-180-CO |

12 |

Resistance loop |

μΩ |

≤140 |

13 |

Rated gas pressure (20℃ gauge) |

Mpa |

0.02 |

14 |

Minimum operating gas pressure |

Mpa |

0 |

15 |

Mechanical life - Circuit breaker |

N |

10000 |

Mechanical life - Load break switch |

N |

3000/6000 |

|

Mechanical life - Disconnector |

N |

3000/6000 |

|

Mechanical life - Earthing switch |

N |

3000/6000 |

|

16 |

Protection grade - Gas tank |

IP67 |

|

Protection grade - Shell |

IP4X |

||

17 |

Rated annual air leakage rate |

% |

0.01 |

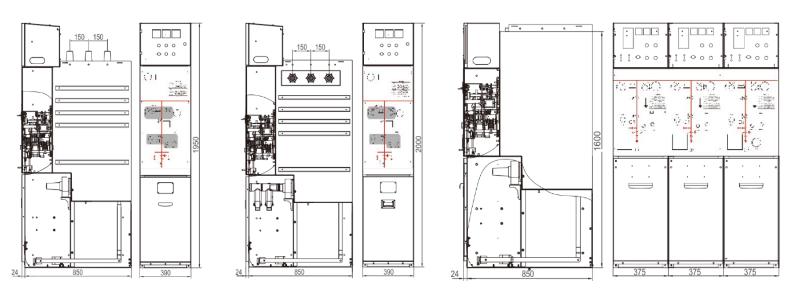

Compact type pure air/nitrogen insulated ring main unit

Type |

Top extension of single panel |

Side extension of single panel |

Single panel size of compact module |

Circuit Breaker Panel |

390*850*1950 |

390*850*1950 |

390*850*1950 |

Load Break Switch Panel |

390*850*1950 |

390*850*1950 |

390*850*1950 |

PT Panel (with 3phase, 5 columns) |

600*850*1950 |

600*850*1950 |

600*850*1950 |

PT Panel (single phase) |

420*850*1950 |

420*850*2000 |

420*850*1600 |

Bus Riser |

375*850*1950 |

375*850*2000 |

375*850*1600 |

Metering panel |

750*850*1950 |

750*850*2000 |

750*850*1600 |

-

Design Solution of 24kV Dry Air Insulated Ring Main UnitThe combination of Solid Insulation Assist + Dry Air Insulation represents the development direction for 24kV RMUs. By balancing insulation requirements with compactness and employing solid auxiliary insulation, insulation tests can be passed without significantly increasing phase-to-phase and phase-to-ground dimensions. Encapsulating the pole column solidifies the insulation for the vacuum interrupter and its connecting conductors.Maintaining the 24kV outgoing busbar phase spacing at 110mm,16/08-2025

Design Solution of 24kV Dry Air Insulated Ring Main UnitThe combination of Solid Insulation Assist + Dry Air Insulation represents the development direction for 24kV RMUs. By balancing insulation requirements with compactness and employing solid auxiliary insulation, insulation tests can be passed without significantly increasing phase-to-phase and phase-to-ground dimensions. Encapsulating the pole column solidifies the insulation for the vacuum interrupter and its connecting conductors.Maintaining the 24kV outgoing busbar phase spacing at 110mm,16/08-2025 -

Optimization Design Scheme for the 12kV Air-Insulated Ring Main Unit Isolating Gap to Reduce Breakdown Discharge ProbabilityWith the rapid development of the power industry, the ecological concept of low-carbon, energy-saving, and environmental protection has been deeply integrated into the design and manufacturing of power supply and distribution electrical products. The Ring Main Unit (RMU) is a key electrical device in distribution networks. Safety, environmental protection, operational reliability, energy efficiency, and economy are inevitable trends in its development. Traditional RMUs are primarily represented16/08-2025

Optimization Design Scheme for the 12kV Air-Insulated Ring Main Unit Isolating Gap to Reduce Breakdown Discharge ProbabilityWith the rapid development of the power industry, the ecological concept of low-carbon, energy-saving, and environmental protection has been deeply integrated into the design and manufacturing of power supply and distribution electrical products. The Ring Main Unit (RMU) is a key electrical device in distribution networks. Safety, environmental protection, operational reliability, energy efficiency, and economy are inevitable trends in its development. Traditional RMUs are primarily represented16/08-2025 -

Analysis of Common Problems in 10kV Gas-Insulated Ring Main Units (RMUs)Introduction:10kV gas-insulated RMUs are widely used due to their numerous advantages, such as being fully enclosed, possessing high insulation performance, requiring no maintenance, having a compact size, and offering flexible and convenient installation. At this stage, they have gradually become a critical node in urban distribution network ring-main power supply and play a significant role in the power distribution system. Problems within gas-insulated RMUs can severely impact the entire di16/08-2025

Analysis of Common Problems in 10kV Gas-Insulated Ring Main Units (RMUs)Introduction:10kV gas-insulated RMUs are widely used due to their numerous advantages, such as being fully enclosed, possessing high insulation performance, requiring no maintenance, having a compact size, and offering flexible and convenient installation. At this stage, they have gradually become a critical node in urban distribution network ring-main power supply and play a significant role in the power distribution system. Problems within gas-insulated RMUs can severely impact the entire di16/08-2025 -

SF6-Free Solution for Air-Insulated/Eco-friendly Gas Ring Main UnitsⅠ. Technical Bottlenecks of SF₆ SubstitutionInsulation Medium Performance Gapo Dried Air/N₂ insulation strength is only 1/3 of SF₆, requiring expansion of contact gap from 60mm to ≥150mm.o Conventional spring mechanisms lack energy to drive rapid closure of large gaps, easily causing contact ablation due to pre-strike.o Synthetic gases (e.g., C4+CO₂) decompose under arcing, leading to irreversible insulation degradation.Mechanical Structural Limitationso National Grid standardization fix16/08-2025

SF6-Free Solution for Air-Insulated/Eco-friendly Gas Ring Main UnitsⅠ. Technical Bottlenecks of SF₆ SubstitutionInsulation Medium Performance Gapo Dried Air/N₂ insulation strength is only 1/3 of SF₆, requiring expansion of contact gap from 60mm to ≥150mm.o Conventional spring mechanisms lack energy to drive rapid closure of large gaps, easily causing contact ablation due to pre-strike.o Synthetic gases (e.g., C4+CO₂) decompose under arcing, leading to irreversible insulation degradation.Mechanical Structural Limitationso National Grid standardization fix16/08-2025 -

Implementation Scheme for Installing Lightning Arresters or Voltage Transformers in Gas-Insulated Ring Main UnitsAccording to insulation type, ring main units (RMUs) can be categorized as gas-insulated or air-insulated. The former installs primary circuit components in a sealed metal enclosure filled with low-pressure gas (primarily SF₆ or mixed gases) as the insulating medium, using cable terminals for incoming and outgoing lines. Due to superior insulation, compact size, and modular design, they are widely used in 10kV outdoor distribution substations and prefabricated transformer stations. However, thei16/08-2025

Implementation Scheme for Installing Lightning Arresters or Voltage Transformers in Gas-Insulated Ring Main UnitsAccording to insulation type, ring main units (RMUs) can be categorized as gas-insulated or air-insulated. The former installs primary circuit components in a sealed metal enclosure filled with low-pressure gas (primarily SF₆ or mixed gases) as the insulating medium, using cable terminals for incoming and outgoing lines. Due to superior insulation, compact size, and modular design, they are widely used in 10kV outdoor distribution substations and prefabricated transformer stations. However, thei16/08-2025 -

Pressure Relief Safety Solution for Gas-Insulated Ring Main UnitsⅠ. Problem ContextAs a core component in urban power distribution networks, ring main units (RMUs) are widely used in residential areas, factories, and public buildings due to their compact structure, low cost, and high reliability. However, internal equipment failures or arc faults may generate high-temperature, high-pressure gas, leading to cabinet explosions that endanger personnel and equipment. While traditional sealed designs maintain insulation integrity, they fail to rapidly release sud16/08-2025

Pressure Relief Safety Solution for Gas-Insulated Ring Main UnitsⅠ. Problem ContextAs a core component in urban power distribution networks, ring main units (RMUs) are widely used in residential areas, factories, and public buildings due to their compact structure, low cost, and high reliability. However, internal equipment failures or arc faults may generate high-temperature, high-pressure gas, leading to cabinet explosions that endanger personnel and equipment. While traditional sealed designs maintain insulation integrity, they fail to rapidly release sud16/08-2025