| Brand | ROCKWILL |

| Model NO. | 27kV Outdoor High - Voltage Vacuum Recloser |

| Rated voltage | 27kV |

| Rated normal current | 1250A |

| Rated short circuit breaking current | 25kA |

| Power frequency withstand voltage | 70kV/min |

| Rated lightning impulse voltage | 150kV |

| manual closing | No |

| Mechanical lock | No |

| Series | RCW |

Description:

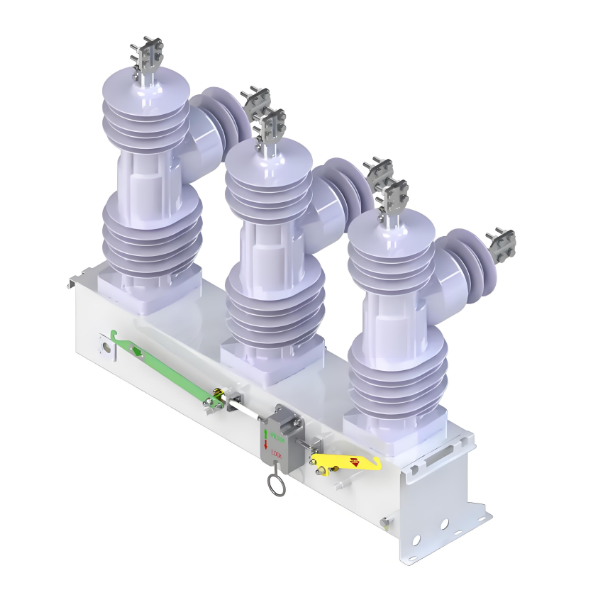

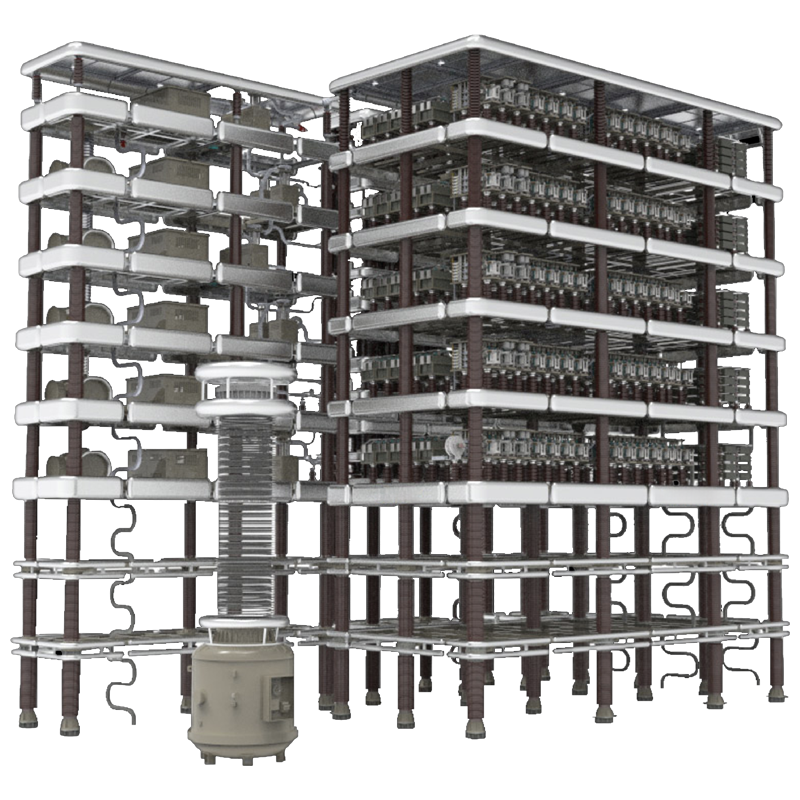

The RCW series automatic circuit reclosers are designed for use in overhead distribution lines and distribution substations. They are compatible with power systems operating at 50/60Hz, covering voltage classes from 11kV to 38kV. With a rated current capacity of up to 1250A, these reclosers integrate multiple functions, including control, protection, measurement, communication, fault detection, and real - time monitoring of closing and opening operations. Composed of an integration terminal, current transformer, permanent magnetic actuator, and a dedicated recloser controller, the RCW series vacuum reclosers offer a comprehensive solution for power distribution network management.

Features:

Flexible Current Ratings: Optional ratings within the rated current range to suit diverse application needs.

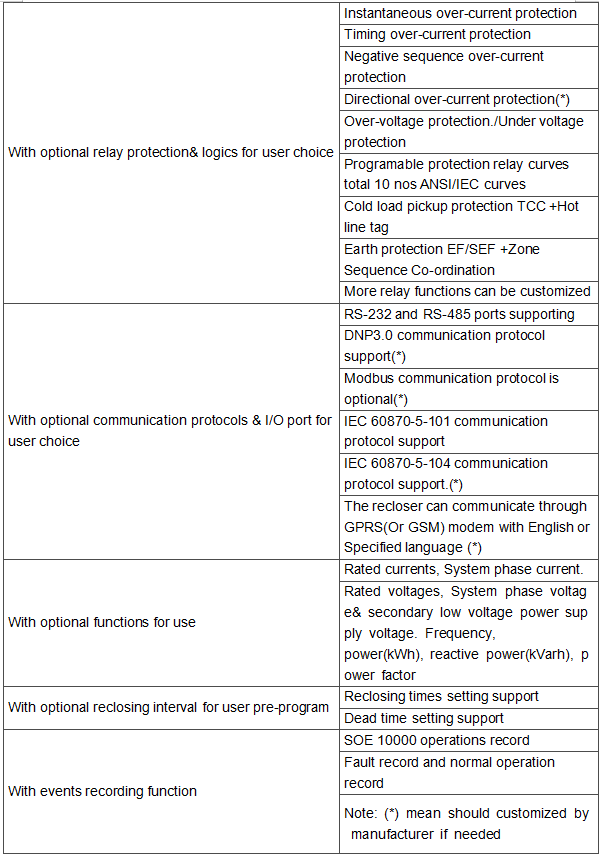

Customizable Protection: A variety of optional relay protection and logic schemes for users to choose from, ensuring adaptability to different system requirements.

Versatile Communication: Optional communication protocols and I/O ports available, enabling seamless integration with various monitoring and control systems.

User - Friendly Software: Equipped with PC software that supports controller testing, setup, programming, and updates, simplifying operation and maintenance.

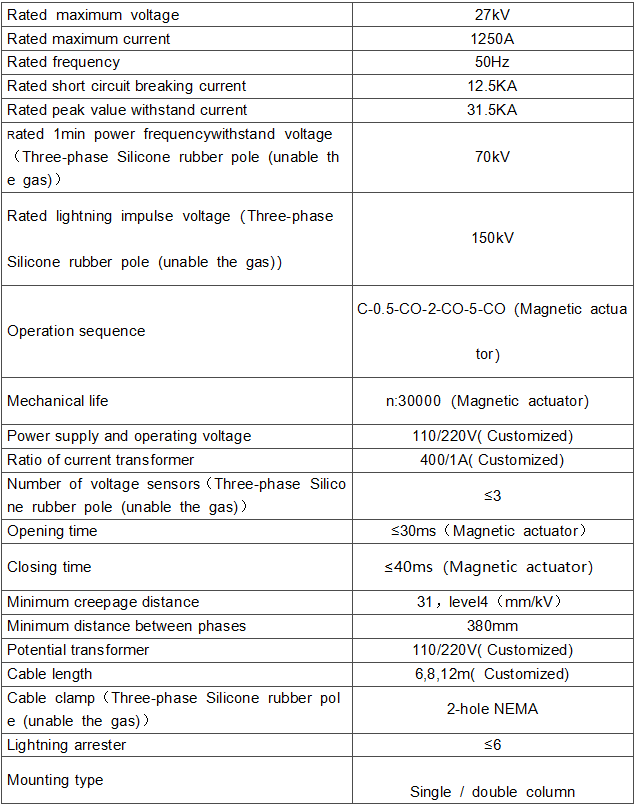

Parameters:

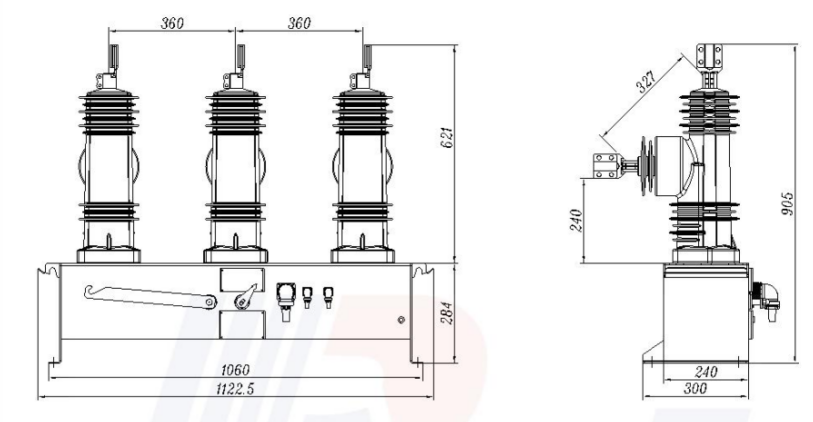

External dimensions:

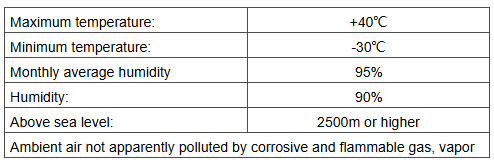

Environmental requirement:

What are the key points for the selection of outdoor vacuum reclosers?

System Parameter Matching: Choose a recloser that matches the rated voltage, rated current, and short-circuit current levels of the power system. Ensure that the rated voltage of the recloser is equal to or higher than the system voltage, the rated current meets the requirements of the line load current, and the rated short-circuit breaking and making currents are greater than the maximum possible short-circuit current in the system.

Reclosing Performance Requirements: Consider the specific requirements of the power system for the reclosing function, such as the number of reclosures, reclosing time intervals, and reclosing success rate. Based on different application scenarios and power supply reliability requirements, select a recloser with appropriate reclosing performance. For example, for critical power supply lines, a recloser with a higher number of reclosures and flexible reclosing time intervals may be required.

Type of Operating Mechanism: Choose an appropriate operating mechanism based on actual needs. Spring-operated mechanisms are suitable for outdoor environments where high reliability is required and maintenance conditions are relatively poor. Permanent magnet-operated mechanisms are better suited for applications requiring high action speed and frequent operations.

Environmental Adaptability: Given the harsh conditions of outdoor environments, consider the environmental adaptability of the recloser. This includes weather resistance, pollution resistance, and water and dustproof performance. Selecting a recloser with good environmental adaptability ensures stable performance during long-term outdoor operation.

Brand and Quality: Choose well-known brands and high-quality recloser products. These products have strict quality control systems in design, manufacturing, and testing, ensuring the performance and reliability of the product. Additionally, good after-sales service is an important factor to consider when choosing a brand, as it ensures timely resolution of issues that may arise during equipment operation.

1. Environmentally friendly gas mixed insulation technology

CO ₂ and perfluoroketone/nitrile mixture gases: such as CO ₂/C ₅ - PFK (perfluoroketone) or CO ₂/C ₄ - PFN (perfluoronitrile) mixture gases. These mixed gases combine the arc extinguishing ability of CO ₂ and the high dielectric strength of perfluorinated ketones/nitriles, making them a substitute for SF ₆ in high-voltage applications. For example, CO ₂/C ₄ - PFN mixed gas has been commercially applied in high-voltage circuit breakers, with insulation and breaking performance close to SF ₆, and significantly reduced global warming potential (GWP).

Air and perfluoroketone mixed gas: In medium pressure applications, the mixture of air and C ₅ - PFK can be used as an insulation medium. By optimizing the mixing ratio and pressure, insulation performance comparable to SF ₆ can be achieved while reducing environmental impact.

2. Vacuum circuit breaker technology

Vacuum arc extinguishing chamber: Utilizing the high insulation strength and fast arc extinguishing ability in a vacuum environment, it replaces the arc extinguishing function of SF ₆. Vacuum circuit breakers are widely used in the medium and low voltage fields, especially in scenarios with high environmental requirements. Its advantages are no greenhouse gas emissions and excellent arc extinguishing performance, but it needs to solve problems such as vacuum sealing and contact materials.

Combination of vacuum circuit breaker and gas insulation: In some medium voltage switchgear, vacuum circuit breakers are used as breaking elements, combined with dry air or nitrogen as insulation media, to form environmentally friendly gas insulated switchgear (GIS) that balances insulation and arc extinguishing performance.

-

Design Solution of 24kV Dry Air Insulated Ring Main UnitThe combination of Solid Insulation Assist + Dry Air Insulation represents the development direction for 24kV RMUs. By balancing insulation requirements with compactness and employing solid auxiliary insulation, insulation tests can be passed without significantly increasing phase-to-phase and phase-to-ground dimensions. Encapsulating the pole column solidifies the insulation for the vacuum interrupter and its connecting conductors.Maintaining the 24kV outgoing busbar phase spacing at 110mm,16/08-2025

Design Solution of 24kV Dry Air Insulated Ring Main UnitThe combination of Solid Insulation Assist + Dry Air Insulation represents the development direction for 24kV RMUs. By balancing insulation requirements with compactness and employing solid auxiliary insulation, insulation tests can be passed without significantly increasing phase-to-phase and phase-to-ground dimensions. Encapsulating the pole column solidifies the insulation for the vacuum interrupter and its connecting conductors.Maintaining the 24kV outgoing busbar phase spacing at 110mm,16/08-2025 -

Optimization Design Scheme for the 12kV Air-Insulated Ring Main Unit Isolating Gap to Reduce Breakdown Discharge ProbabilityWith the rapid development of the power industry, the ecological concept of low-carbon, energy-saving, and environmental protection has been deeply integrated into the design and manufacturing of power supply and distribution electrical products. The Ring Main Unit (RMU) is a key electrical device in distribution networks. Safety, environmental protection, operational reliability, energy efficiency, and economy are inevitable trends in its development. Traditional RMUs are primarily represented16/08-2025

Optimization Design Scheme for the 12kV Air-Insulated Ring Main Unit Isolating Gap to Reduce Breakdown Discharge ProbabilityWith the rapid development of the power industry, the ecological concept of low-carbon, energy-saving, and environmental protection has been deeply integrated into the design and manufacturing of power supply and distribution electrical products. The Ring Main Unit (RMU) is a key electrical device in distribution networks. Safety, environmental protection, operational reliability, energy efficiency, and economy are inevitable trends in its development. Traditional RMUs are primarily represented16/08-2025 -

Analysis of Common Problems in 10kV Gas-Insulated Ring Main Units (RMUs)Introduction:10kV gas-insulated RMUs are widely used due to their numerous advantages, such as being fully enclosed, possessing high insulation performance, requiring no maintenance, having a compact size, and offering flexible and convenient installation. At this stage, they have gradually become a critical node in urban distribution network ring-main power supply and play a significant role in the power distribution system. Problems within gas-insulated RMUs can severely impact the entire di16/08-2025

Analysis of Common Problems in 10kV Gas-Insulated Ring Main Units (RMUs)Introduction:10kV gas-insulated RMUs are widely used due to their numerous advantages, such as being fully enclosed, possessing high insulation performance, requiring no maintenance, having a compact size, and offering flexible and convenient installation. At this stage, they have gradually become a critical node in urban distribution network ring-main power supply and play a significant role in the power distribution system. Problems within gas-insulated RMUs can severely impact the entire di16/08-2025 -

SF6-Free Solution for Air-Insulated/Eco-friendly Gas Ring Main UnitsⅠ. Technical Bottlenecks of SF₆ SubstitutionInsulation Medium Performance Gapo Dried Air/N₂ insulation strength is only 1/3 of SF₆, requiring expansion of contact gap from 60mm to ≥150mm.o Conventional spring mechanisms lack energy to drive rapid closure of large gaps, easily causing contact ablation due to pre-strike.o Synthetic gases (e.g., C4+CO₂) decompose under arcing, leading to irreversible insulation degradation.Mechanical Structural Limitationso National Grid standardization fix16/08-2025

SF6-Free Solution for Air-Insulated/Eco-friendly Gas Ring Main UnitsⅠ. Technical Bottlenecks of SF₆ SubstitutionInsulation Medium Performance Gapo Dried Air/N₂ insulation strength is only 1/3 of SF₆, requiring expansion of contact gap from 60mm to ≥150mm.o Conventional spring mechanisms lack energy to drive rapid closure of large gaps, easily causing contact ablation due to pre-strike.o Synthetic gases (e.g., C4+CO₂) decompose under arcing, leading to irreversible insulation degradation.Mechanical Structural Limitationso National Grid standardization fix16/08-2025 -

Implementation Scheme for Installing Lightning Arresters or Voltage Transformers in Gas-Insulated Ring Main UnitsAccording to insulation type, ring main units (RMUs) can be categorized as gas-insulated or air-insulated. The former installs primary circuit components in a sealed metal enclosure filled with low-pressure gas (primarily SF₆ or mixed gases) as the insulating medium, using cable terminals for incoming and outgoing lines. Due to superior insulation, compact size, and modular design, they are widely used in 10kV outdoor distribution substations and prefabricated transformer stations. However, thei16/08-2025

Implementation Scheme for Installing Lightning Arresters or Voltage Transformers in Gas-Insulated Ring Main UnitsAccording to insulation type, ring main units (RMUs) can be categorized as gas-insulated or air-insulated. The former installs primary circuit components in a sealed metal enclosure filled with low-pressure gas (primarily SF₆ or mixed gases) as the insulating medium, using cable terminals for incoming and outgoing lines. Due to superior insulation, compact size, and modular design, they are widely used in 10kV outdoor distribution substations and prefabricated transformer stations. However, thei16/08-2025 -

Pressure Relief Safety Solution for Gas-Insulated Ring Main UnitsⅠ. Problem ContextAs a core component in urban power distribution networks, ring main units (RMUs) are widely used in residential areas, factories, and public buildings due to their compact structure, low cost, and high reliability. However, internal equipment failures or arc faults may generate high-temperature, high-pressure gas, leading to cabinet explosions that endanger personnel and equipment. While traditional sealed designs maintain insulation integrity, they fail to rapidly release sud16/08-2025

Pressure Relief Safety Solution for Gas-Insulated Ring Main UnitsⅠ. Problem ContextAs a core component in urban power distribution networks, ring main units (RMUs) are widely used in residential areas, factories, and public buildings due to their compact structure, low cost, and high reliability. However, internal equipment failures or arc faults may generate high-temperature, high-pressure gas, leading to cabinet explosions that endanger personnel and equipment. While traditional sealed designs maintain insulation integrity, they fail to rapidly release sud16/08-2025