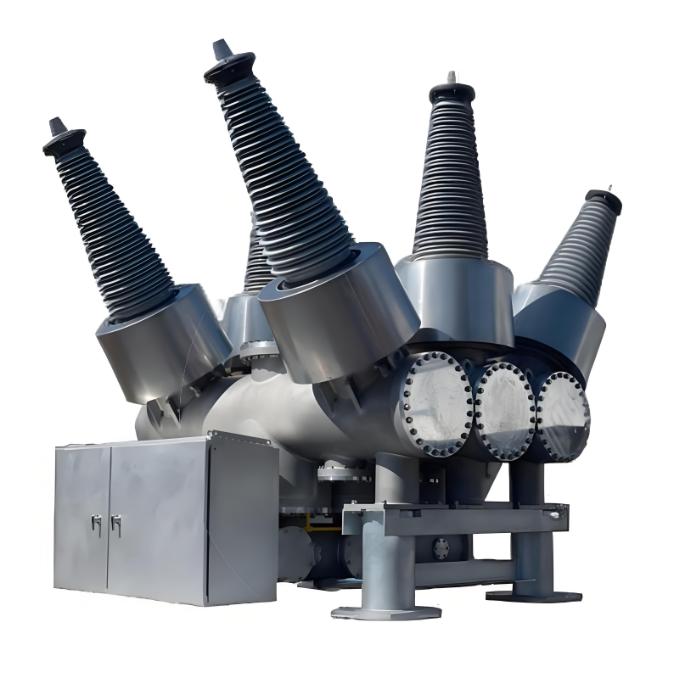

145kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker

| Brand | ROCKWILL |

| Model NO. | 145kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker |

| Rated voltage | 145kV |

| Rated normal current | 3000A |

| Rated frequency | 50/60Hz |

| Series | MAS |

Description

The 145kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker (VCB) is a cutting-edge high-voltage power equipment engineered for eco-friendly, reliable grid operation. Developed to address the environmental concerns of traditional SF₆-insulated breakers, it integrates Meidensha’s advanced vacuum arc-extinguishing technology and dry air insulation—setting a new standard for sustainable high-voltage circuit breaking.

As a core component in 145kV power transmission and distribution networks, this breaker features a grounded metal tank (dead tank) design that encapsulates key components, ensuring exceptional resistance to harsh environmental conditions such as extreme temperatures, humidity, and pollution. By using dry air (a natural, zero-GWP insulating medium) instead of SF₆, it eliminates greenhouse gas emissions and gas decomposition risks during current interruption. It is widely applied in utility substations, industrial power plants, and renewable energy integration projects, delivering stable, long-term performance while aligning with global low-carbon energy goals.

Core Features

SF₆-Free Eco-Friendly Design:Adopts dry air as the insulating medium (GWP = 0), fully complying with international environmental regulations (e.g., EU F-gas Directive). No risk of gas leakage or decomposition, reducing environmental impact and eliminating the need for SF₆ recovery/disposal processes.

145kV-Level High Reliability:Equipped with high-performance vacuum interrupters, it achieves reliable arc extinction even under rated short-circuit breaking currents (up to 40kA). The dead tank structure enhances insulation stability, ensuring a service life of over 30 years and a mechanical operation life of 10,000 times.

Superior Environmental Adaptability:The hermetically sealed metal tank and corrosion-resistant materials enable stable operation in extreme conditions: temperature range of -30℃ ~ +55℃, altitude up to 3000 meters, and pollution class up to IV. Suitable for both indoor and outdoor installations.

Low Lifecycle Cost:Dry air insulation requires no periodic gas replenishment or pressure monitoring, reducing operation and maintenance (O&M) costs by 50% compared to SF₆ breakers. The modular design also simplifies on-site installation and component replacement.

Enhanced Safety & Smart Integration:The dead tank structure minimizes exposed live parts, lowering electric shock risks for personnel. It supports integration with intelligent monitoring systems to track vacuum degree, tank pressure, and operating status in real time, enabling predictive maintenance and remote grid management.

Product Specifications

Item |

Parameter |

|

Rated Maximum Voltage (kV) |

145 |

|

Dielectric Withstand Voltage |

Power Frequency (1 min Dry) (kV rms) |

275 |

Lightning Impulse (Full Wave Withstand) (kV Peak) |

650 |

|

Rated Frequency (Hz) |

50/60 |

|

Rated Continuous Current (A) |

3000 |

|

Rated Short Circuit Breaking Current (kA) |

40 |

|

Rated Transient Recovery Voltage: Rate of Rise (kV/μs) |

2 |

|

First Pole to Clear Factor |

1.5 |

|

Rated Closing and Latching Current (kA) |

104 |

|

Rated Short-Circuit and Short-Time Circuit (kA) |

40 (3s) |

|

Rated Interrupting Time (Cycles) |

3 |

|

Rated Opening Time (s) |

0.05 |

|

Rated Closing Time with No Load (s) |

0.13 |

|

Operating Duty |

O-0.3s-CO-15s-CO |

|

Rated Control Voltage (Vdc) |

48, 125, 250 |

|

Rated Tripping Voltage (Vdc) |

48, 125, 250 |

|

Rated Motor Voltage |

(Vdc) |

48, 125, 250 |

(Vac) |

60, 120, 240 |

|

Rated Dry Air Pressure (psig) |

130.5 |

|

Closing Operation System |

Spring |

|

Tripping Control System |

Spring |

|

Certifications |

ANSI/IEEE C37.06, IEC 62271-100 |

|

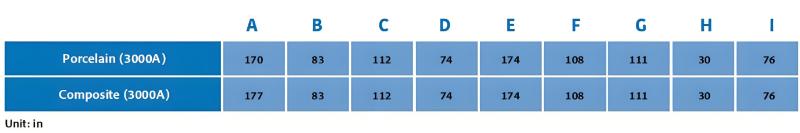

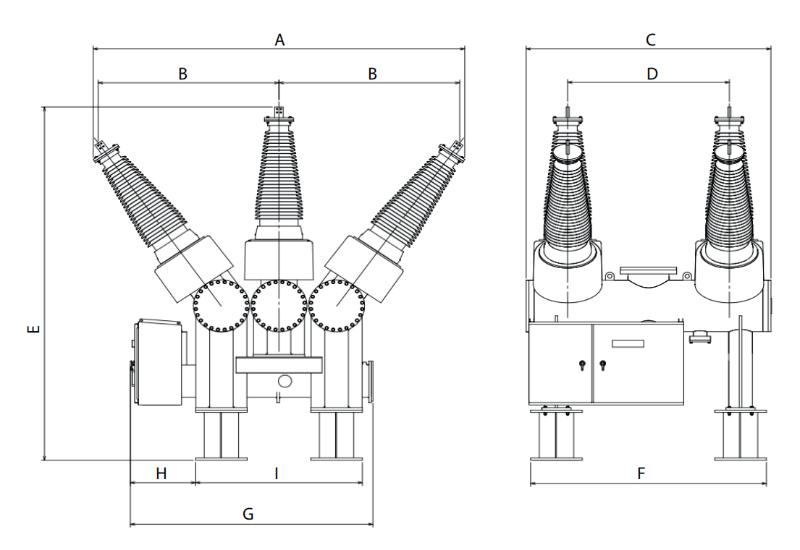

Dimensions

The leakage rate of SF₆ gas must be controlled at an extremely low level, typically not exceeding 1% per year. SF₆ gas is a potent greenhouse gas, with a greenhouse effect 23,900 times that of carbon dioxide. If a leak occurs, it can not only cause environmental pollution but also lead to a decrease in the gas pressure within the arc quenching chamber, affecting the performance and reliability of the circuit breaker.

To monitor the leakage of SF₆ gas, gas leakage detection devices are typically installed on tank-type circuit breakers. These devices help to promptly identify any leaks so that appropriate measures can be taken to address the issue.

Integral Tank Structure:

-

Integral Tank Structure: The breaker's arc quenching chamber, insulating medium, and related components are sealed within a metal tank filled with an insulating gas (such as sulfur hexafluoride) or insulating oil. This forms a relatively independent and sealed space, effectively preventing external environmental factors from affecting the internal components. This design enhances the insulation performance and reliability of the equipment, making it suitable for various harsh outdoor environments.

Arc Quenching Chamber Layout:

-

Arc Quenching Chamber Layout: The arc quenching chamber is typically installed inside the tank. Its structure is designed to be compact, enabling efficient arc quenching within a limited space. Depending on different arc quenching principles and technologies, the specific construction of the arc quenching chamber may vary, but generally includes key components such as contacts, nozzles, and insulating materials. These components work together to ensure that the arc is quickly and effectively extinguished when the breaker interrupts the current.

Operating Mechanism:

-

Operating Mechanism: Common operating mechanisms include spring-operated mechanisms and hydraulic-operated mechanisms.

-

Spring-Operated Mechanism: This type of mechanism is simple in structure, highly reliable, and easy to maintain. It drives the opening and closing operations of the breaker through the energy storage and release of springs.

-

Hydraulic-Operated Mechanism: This mechanism offers advantages such as high output power and smooth operation, making it suitable for high-voltage and high-current class breakers.