Customization 50MVA 161kV 170kV 220kV transformer for power transmission

| Brand | ROCKWILL |

| Model NO. | 50MVA 220kV transformer for power transmission |

| Rated frequency | 50/60Hz |

| Series | S |

Description of 161kV 170kV 220kV Transmission Transformer

As a pioneer in China's power transformer industry, we have specialized in the R&D and manufacturing of power transformer equipment for decades, and established industry standards with core technologies.

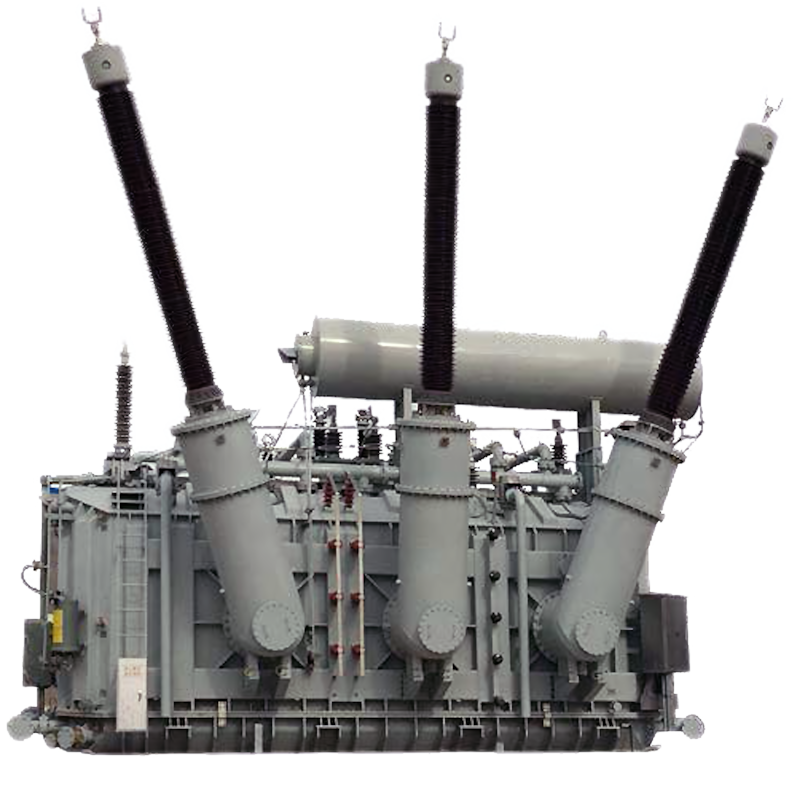

A 161kV 170kV 220kV Transmission Transformer is a key high-voltage power equipment in regional and intercity power grids. It bridges higher-voltage transmission networks (e.g., 500kV) and medium-voltage distribution systems (e.g., 110kV/35kV), stepping down 220kV electricity to lower levels for industrial zones, urban centers, and large-scale infrastructure. Widely deployed in substations and grid interconnection points, it ensures stable power flow over medium-to-long distances (50–200km), supports load balancing, and enhances the reliability of energy distribution across provinces or metropolitan areas.

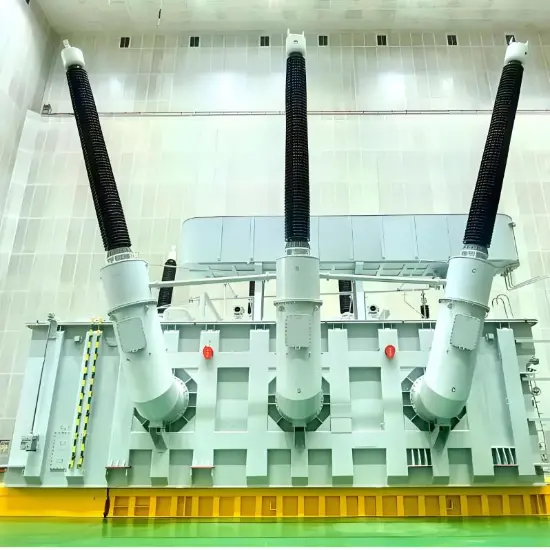

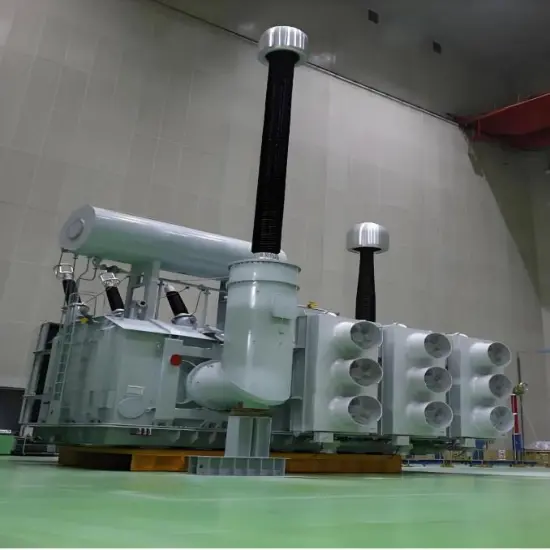

50MVA 220kV Transformer

The voltage classes of some of these Power Transformer include 110kV 115kV 123kV 125kV 126kV 132kV 138kV 145kV 150kV 154kV 161kV 170kV 220kV 225kV 230kV 245kV 275kV 330kV 345kV 363kV 380kV 400kV 500kV Power transformers of voltage ,and aboveand customization is available.

This power transformer is fully compliant with international standards including IEC 60076-1, IEEE C57.12.00, ANSI C57.12.90, AS/NZS 60076.5 and EN 61558-1. It meets quality requirements and is widely adaptable to the operational needs of power grids in multiple overseas regions.

Features of 161kV 170kV 220kV Transmission Transformer

Versatile Voltage Matching: Optimized to connect 220kV grids with lower-voltage systems (110kV/35kV), enabling flexible integration into multi-level power networks. This adaptability makes it suitable for both urban and rural transmission scenarios.

High Efficiency & Low Loss: Adopts low-loss silicon steel cores and optimized copper windings, reducing no-load and load losses by 15–20% compared to older models. Meets international efficiency standards (e.g., IEC 60076) to minimize energy waste during transmission.

Robust Structural Design: Built with sealed oil-immersed tanks or advanced dry-type insulation (for indoor use) to resist moisture, dust, and extreme temperatures (-30°C to 45°C). Corrosion-resistant coatings ensure durability in coastal or industrial environments.

Enhanced Safety Mechanisms: Equipped with pressure relief valves, temperature sensors, and gas relay protection to detect faults like short circuits or oil leaks. On-load tap changers (OLTC) allow voltage adjustment under full load, preventing grid instability.

Compact & Space-Saving: Designed with reduced footprint for easy installation in urban substations with limited space. Noise-dampening features (e.g., vibration-absorbing bases) comply with environmental regulations in residential areas.

Smart Grid Integration: Integrated with IoT-enabled monitoring systems to track real-time parameters (oil quality, winding temperature, load current). Supports remote diagnostics and predictive maintenance, reducing downtime.

High Short-Circuit Withstand Capacity: Reinforced windings and rigid core structures withstand transient short-circuit currents, ensuring operational safety during grid faults and extending service life (typically 30+ years).

Application Field

Power Plant Step-up Substation

Industrial Power System

Hub Substation