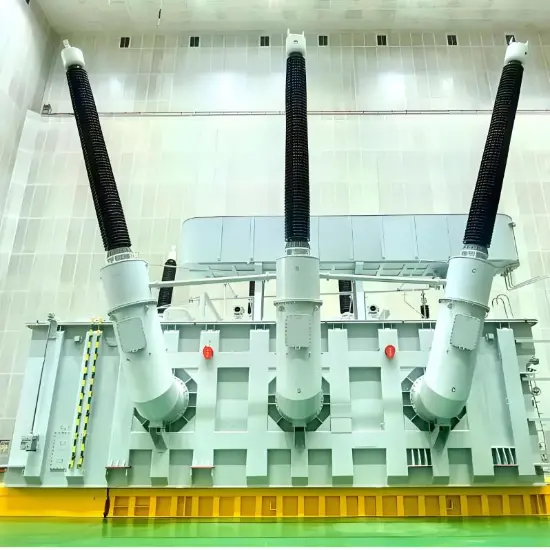

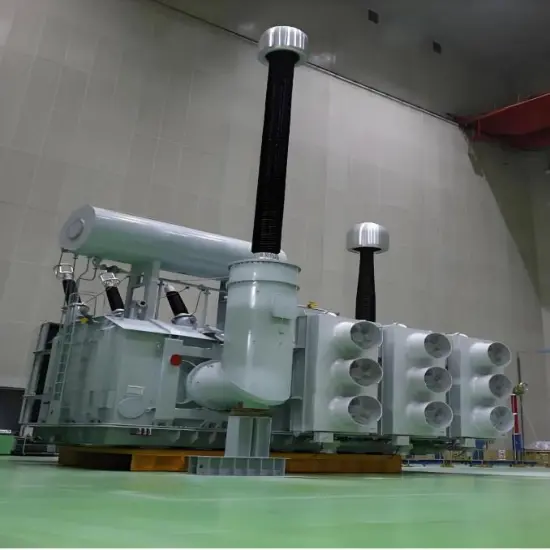

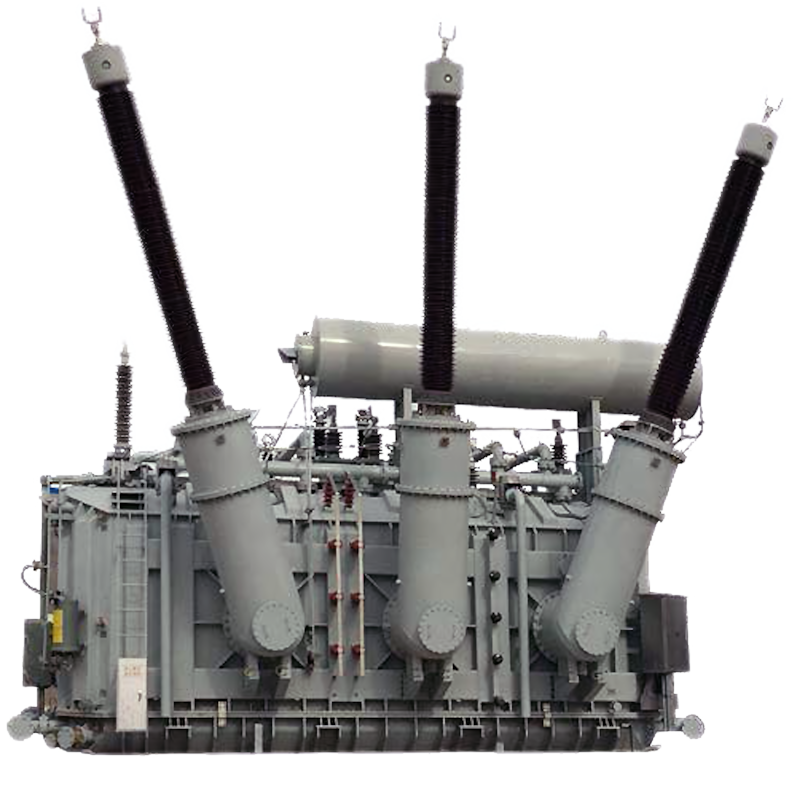

Rock wool electric furnace transformer

| Brand | ROCKWILL |

| Model NO. | Rock wool electric furnace transformer |

| Rated frequency | 50/60Hz |

| Series | RYDL |

Overview

Electroslag furnaces are used for remelting and refining steels produced by ordinary smelting methods, and they generally adopt single-phase power supply.They are specially used as power sources for electroslag furnaces in the production of aviation bearing steel, superalloys, resistance alloys, precision alloys, certain non-ferrous metals, etc. They can also be used to produce large high-quality alloy steel ingots, large slab ingots, slabs and other special shaped castings.Electroslag furnace transformers are all without reactors. Unlike arc furnace transformers used in electroslag metallurgy and electric arc steelmaking, when arcing and slag forming are carried out by directly using electrodes plus auxiliary steel scraps, there is an arc only in the initial stage. After slag forming is completed, it turns into an essentially arc-free electroslag process, which continues until the end of smelting. Therefore, the transformer for electroslag furnace power supply requires a low no-load voltage and a small impedance voltage.The low-voltage side of the electroslag furnace transformer must have voltage regulation grades. The voltage regulation methods include: 1. No-excitation off-load voltage regulation; 2. Excited off-load voltage regulation; 3. On-load voltage regulation. Regardless of the voltage regulation method adopted, the adjustment is performed through the switch on the high-voltage coil.

Feature

Specifically designed for rock wool production electric furnaces, it can adapt to the high-power requirements of high-temperature melting processes, ensure stable power supply, and meet the continuous power output required for key stages such as rock wool melting and 纤维化.

Equipped with multi-stage voltage regulation function, it can flexibly adjust the voltage according to the power requirements of different stages of rock wool smelting (such as raw material melting, heat preservation and shaping), improving energy utilization efficiency.

Adopting an enhanced cooling system (such as oil-immersed self-cooling or forced air cooling), it can adapt to the high-temperature environment generated by the long-term continuous operation of rock wool electric furnaces, ensuring stable and reliable operation of the equipment.

It has strong overload capacity, which can cope with short-term load fluctuations during the start-up of the electric furnace or the input of raw materials, reducing the risk of shutdown caused by load impact.

The compact structural design is suitable for the spatial layout of rock wool production lines, and it has excellent insulation performance, which can maintain good operating conditions in industrial environments with high dust and high temperature.