330kV 345kV 363 kV 380kV Dead tank SF6 circuit breaker supplier

| Brand | ROCKWILL |

| Model NO. | 363 kV Dead tank SF6 circuit breaker |

| Rated voltage | 363kV |

| Rated normal current | 4000A |

| Rated frequency | 50/60Hz |

| Series | LW |

Description

Pioneers in China's GIS tank circuit breaker industry. As the country's first source factory specializing in this field, we boast decades of technical accumulation and continuous innovation — ensuring reliable products while leading the way in R&D. Thanks to our outstanding reliability, we've been chosen for numerous major power projects.

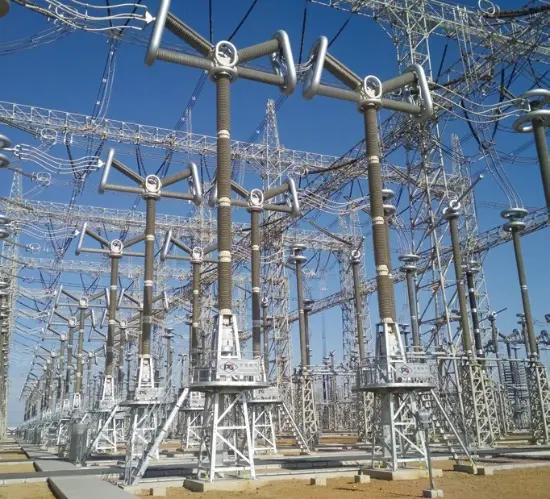

330kV 345kV 363 kV 380kV Dead tank SF6 circuit breaker are composed of components such as inlet/outlet bushings, current transformers, arc extinguishers, frames, and operating mechanisms. They can cut off rated current, fault current, or switch lines to control and protect power systems, widely used in power, metallurgy, mining, transportation, and utilities industries at home and abroad.

Main Features

Technical specifications

Among these, some SF6 tank circuit breakers cover non-standard voltage levels including 138kV, 225kV, 230kV, 245kV, 275kV, 330kV, 345kV, 400kV, 756kV, and 800kV (note: 145kV is a standard voltage level, adjusted for accuracy), with a rated short-circuit breaking current of 50kA or 63kA, and we offer customization services.

Serial number |

project |

parameters |

1 |

Rated voltage |

330kV 345kV 363kV 380kV |

2 |

Rated Current |

4000A |

3 |

Rated frequency |

50/60Hz |

4 |

Rated short-circuit breaking current |

50kA |

5 |

Rated short-circuit closing current |

130kA |

6 |

Rated short-time withstand current and duration |

50kA/3s |

7 |

Rated peak withstand current |

130kA |

8 |

Mechanical life |

M2 |

330kV/345kV/363kV/380kV Dead Tank SF6 Circuit Breaker - Operating Environment Conditions

Ambient Temperature:Standard range -30℃ ~ +40℃;optional -40℃ ~ +45℃ for extreme climates (equipped with anti-freezing heating components or high-temperature heat dissipation structure).

Altitude:≤ 1000m above sea level (standard configuration). For 1000m~2500m, insulation derating design is adopted to compensate for air insulation attenuation.

Relative Humidity:Monthly average ≤ 90% (at 25℃);daily average ≤ 95%;no persistent condensation on the tank body to avoid insulation degradation.

Wind Speed:Maximum sustained wind speed ≤ 34m/s (12-level wind);instantaneous gust ≤ 50m/s;structural design resists wind load and vibration.

Atmospheric Pollution:Suitable for pollution degree Class III (GB/T 16434) or equivalent IEC 60694 standards. For coastal salt fog or industrial corrosive areas, optional anti-corrosion coating (epoxy powder spraying) and sealed insulation assembly are available.

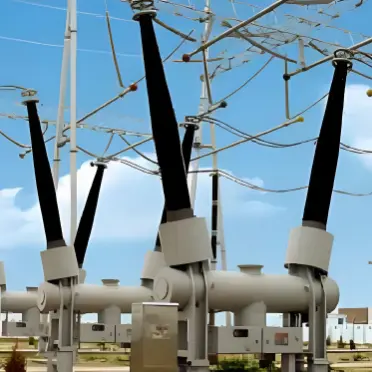

Integral Tank Structure:

-

Integral Tank Structure: The breaker's arc quenching chamber, insulating medium, and related components are sealed within a metal tank filled with an insulating gas (such as sulfur hexafluoride) or insulating oil. This forms a relatively independent and sealed space, effectively preventing external environmental factors from affecting the internal components. This design enhances the insulation performance and reliability of the equipment, making it suitable for various harsh outdoor environments.

Arc Quenching Chamber Layout:

-

Arc Quenching Chamber Layout: The arc quenching chamber is typically installed inside the tank. Its structure is designed to be compact, enabling efficient arc quenching within a limited space. Depending on different arc quenching principles and technologies, the specific construction of the arc quenching chamber may vary, but generally includes key components such as contacts, nozzles, and insulating materials. These components work together to ensure that the arc is quickly and effectively extinguished when the breaker interrupts the current.

Operating Mechanism:

-

Operating Mechanism: Common operating mechanisms include spring-operated mechanisms and hydraulic-operated mechanisms.

-

Spring-Operated Mechanism: This type of mechanism is simple in structure, highly reliable, and easy to maintain. It drives the opening and closing operations of the breaker through the energy storage and release of springs.

-

Hydraulic-Operated Mechanism: This mechanism offers advantages such as high output power and smooth operation, making it suitable for high-voltage and high-current class breakers.

The leakage rate of SF₆ gas must be controlled at an extremely low level, typically not exceeding 1% per year. SF₆ gas is a potent greenhouse gas, with a greenhouse effect 23,900 times that of carbon dioxide. If a leak occurs, it can not only cause environmental pollution but also lead to a decrease in the gas pressure within the arc quenching chamber, affecting the performance and reliability of the circuit breaker.

To monitor the leakage of SF₆ gas, gas leakage detection devices are typically installed on tank-type circuit breakers. These devices help to promptly identify any leaks so that appropriate measures can be taken to address the issue.

During the normal operation and interruption processes of a circuit breaker, SF₆ gas can decompose, producing various decomposition products such as SF₄, S₂F₂, SOF₂, HF, and SO₂. These decomposition products are often corrosive, toxic, or irritating, and therefore require monitoring.If the concentration of these decomposition products exceeds certain limits, it may indicate abnormal discharges or other faults within the arc quenching chamber. Timely maintenance and handling are necessary to prevent further damage to the equipment and to safeguard personnel health.

They are mainly suitable for 330kV and above high-voltage power transmission and transformation projects. Focus on three key points for selection: ① Voltage matching — Select the corresponding grade according to power grid standards: 345kV is compatible with the American standard system, and 363kV/380kV are suitable for special high-voltage working conditions; ② Key parameters — Short-circuit breaking current ≥50kA, and the rated SF6 pressure increases with voltage upgrade (about 0.75MPa for 380kV); ③ Scenario adaptation — For high-altitude/coastal areas, choose customized models with enhanced insulation and corrosion resistance, and a third-party type test report must be provided.

They are mainly suitable for 330kV and above high-voltage power transmission and transformation projects. Focus on three key points for selection: ① Voltage matching — Select the corresponding grade according to power grid standards: 345kV is compatible with the American standard system, and 363kV/380kV are suitable for special high-voltage working conditions; ② Key parameters — Short-circuit breaking current ≥50kA, and the rated SF6 pressure increases with voltage upgrade (about 0.75MPa for 380kV); ③ Scenario adaptation — For high-altitude/coastal areas, choose customized models with enhanced insulation and corrosion resistance, and a third-party type test report must be provided.