Overview

Submerged arc furnaces are a general term for various submerged arc furnaces such as ferroalloy furnaces, calcium carbide furnaces, yellow phosphorus furnaces, fused corundum furnaces, boron carbide furnaces, and cyanide salt furnaces.

Applications

It is mainly used for reduction smelting of raw materials such as ores and carbonaceous reducing agents.

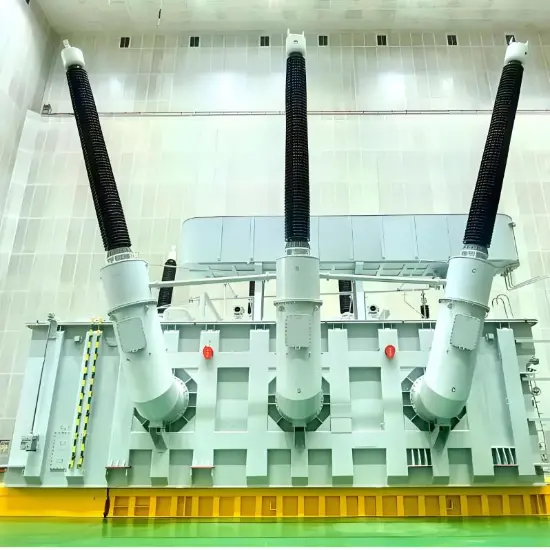

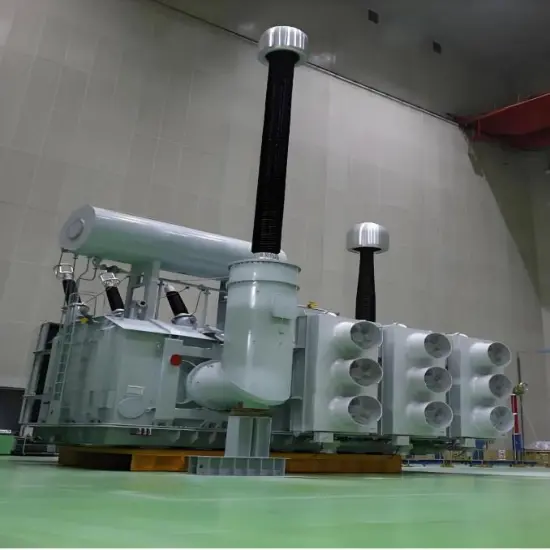

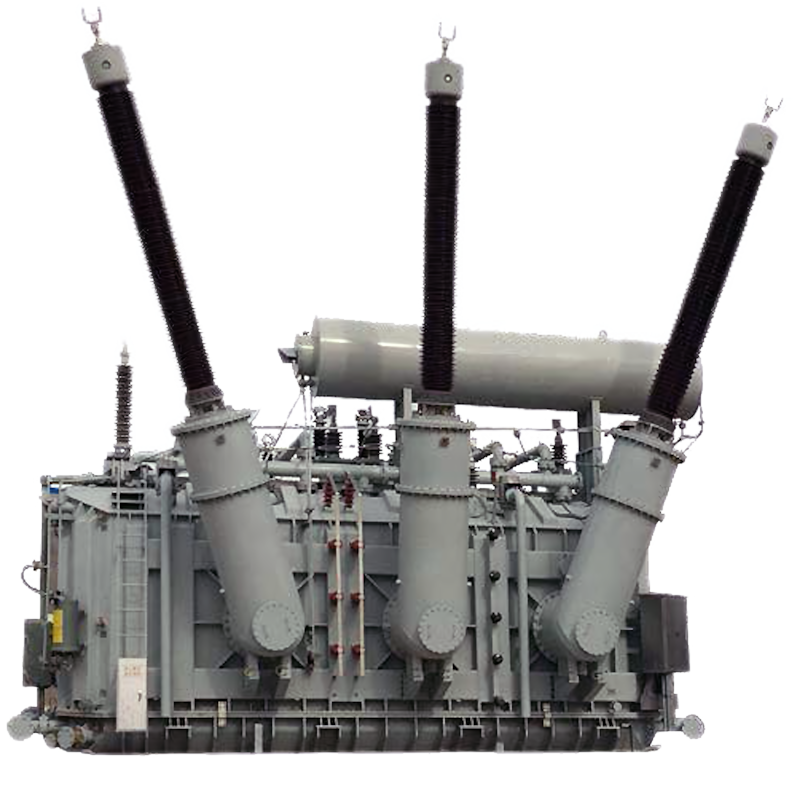

Structural Features

Submerged arc furnace transformers have continuous and stable loads, low impedance voltage, more voltage regulation levels with smaller step differences, and strong overload capacity. They can be divided into two types: on-load voltage regulation and no-excitation voltage regulation. Generally, the first few levels output constant capacity, and the latter few levels output constant current.

Feature

Specifically designed for various submerged arc furnaces (such as ferroalloy furnaces and calcium carbide furnaces), it can continuously and stably output high power, accurately match the continuous production needs of ore reduction smelting, and ensure uninterrupted high-temperature smelting processes.

It has excellent impedance voltage regulation characteristics with multiple voltage regulation levels and small step differences. It can achieve precise voltage regulation through on-load or no-excitation voltage regulation methods, adapting to the arc characteristic requirements of different stages such as furnace charge melting and reduction.

It has strong overload capacity, capable of coping with short-term load fluctuations caused by changes in furnace charge ratio and electrode position during smelting, ensuring production stability.

With low impedance voltage, the first few levels achieve constant capacity output and the latter few levels maintain constant current output, optimizing electrical energy conversion efficiency and meeting the power and current requirements of different smelting stages.

The structural design enhances heat dissipation and mechanical strength, and adopts an efficient cooling system (such as forced oil circulation), enabling long-term stable operation in high-dust and high-temperature smelting environments and extending equipment service life.