Overview

Power frequency induction furnaces use power frequency power directly and melt metals based on the principle of electromagnetic induction. They are widely used for melting ferrous and non-ferrous metals, as well as various high-grade cast iron, malleable cast iron, ductile iron, etc.

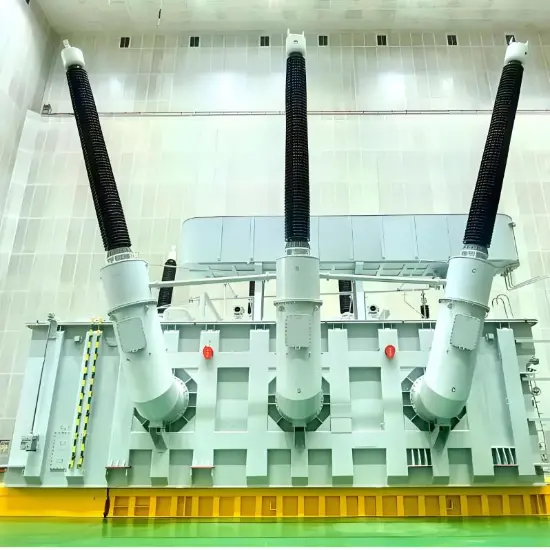

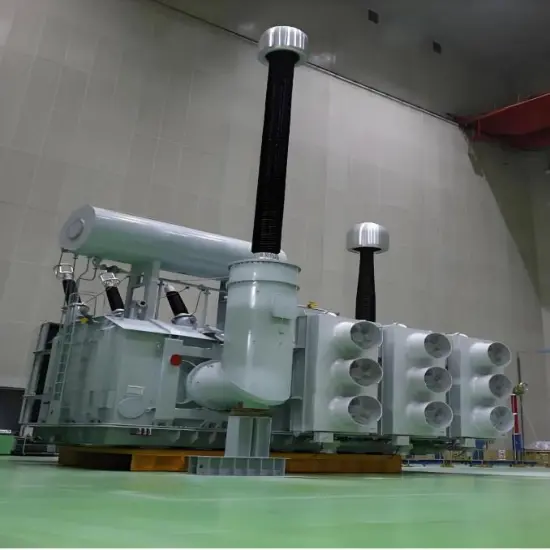

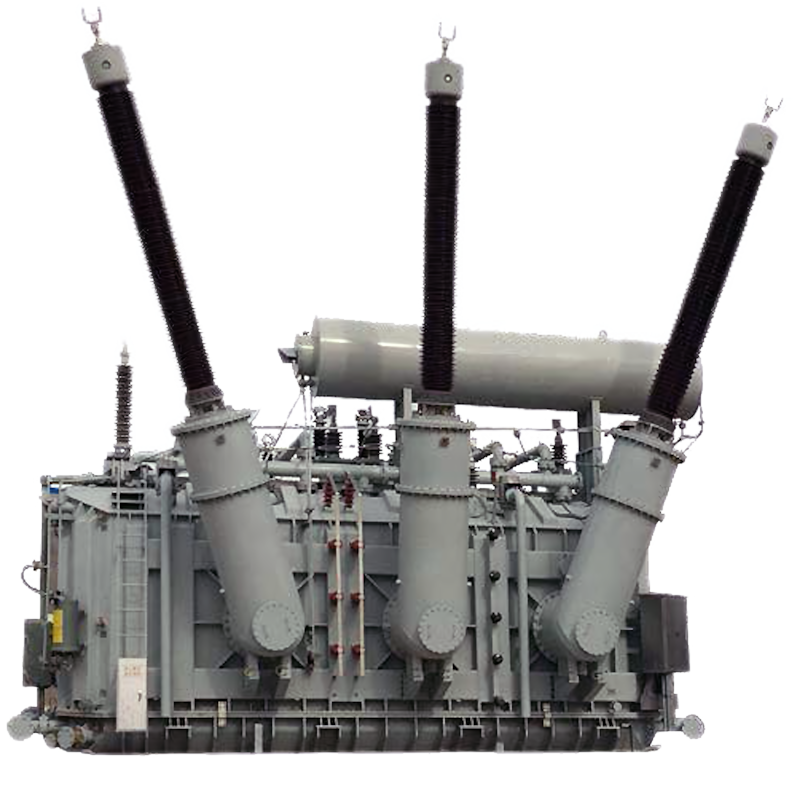

Structural Features

The load power supply of power frequency furnace transformers is stable, and there is generally no requirement for overload capacity. To improve efficiency, they have low impedance voltage and a hard external characteristic. Their structural design features are similar to those of power transformers with the same capacity, with differences only in voltage regulation methods and voltage regulation ranges.

Feature

Specifically designed for power frequency induction furnaces, it directly adapts to power frequency power supplies (50Hz/60Hz) and provides stable electricity for metal melting through the principle of electromagnetic induction, accurately meeting the smelting needs of ferrous and non-ferrous metals as well as various types of cast iron.

It has stable load characteristics with no special overload requirements. The power output is stable during operation, which can reduce interference to the smelting process caused by load fluctuations and ensure consistent quality of metal melting.

It features low impedance voltage and a "hard external characteristic" (small voltage fluctuation with load changes), resulting in high electrical energy conversion efficiency. This can reduce energy loss during smelting and improve production economy.

Its structural design is similar to that of power transformers with the same capacity, but the voltage regulation methods and ranges are more suitable for smelting processes. It can flexibly adjust the output voltage according to the state of the furnace charge (such as solid or liquid) to optimize melting efficiency.

It is suitable for industrial continuous production scenarios, maintaining stable operation even in complex environments such as dust and high temperatures. Additionally, it has low maintenance costs, making it suitable for the production needs of small and medium-sized foundry and smelting enterprises.