36kV 72.5kV Interruptor de Vácuo com Isolamento a Ar Seco e Tanque Morto (VCB)

| Marca | ROCKWILL |

| Número do Modelo | 36kV 72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker(VCB) |

| Tensão nominal | 72.5kV |

| Corrente nominal | 2000A |

| Frequência nominal | 50/60Hz |

| Série | NVBOA |

Descrição

O Disjuntor de Tanque Morto Isolado a Ar Seco nasceu da tecnologia superior e da vasta experiência de produção da Meidensha Corporation. É um disjuntor que utiliza interrompedores a vácuo e ar seco para isolamento. Para não usar SF6, que é um gás de efeito estufa, não há risco de decomposição do gás devido à interrupção de corrente. Portanto, é um disjuntor altamente confiável e de alto desempenho.

Características

Disjuntor de Tanque Morto VCB otimizado para aquisição verde. Utiliza ar seco para isolamento em vez do SF6, que é especificado como gás de efeito estufa. Nosso conceito básico de design é realizar os fatores ambientais no design (os 3Rs (Reduzir, Reutilizar e Reciclar) + LS (Longa duração & Separável)) e a redução do custo total ao longo da vida útil (LCC) como conceitos básicos.

Contribuição para a prevenção do aquecimento global

É empregado o isolamento a ar seco em vez do isolamento com gás SF6. O PGE (Potencial de Aquecimento Global) do SF6 é 23.900.

Excelente desempenho de interrupção

Como cada seção de interrupção de corrente utiliza um interrompedor a vácuo, as características de recuperação de isolamento são excelentes. Ele exibe características superiores em casos de interrupção de curto-circuito e interrupção de falhas em linhas curtas.

Capacidade suficiente contra múltiplos descargas e falhas evolutivas

Como os interrompedores a vácuo utilizados são do tipo totalmente auto-difusão de arco, este disjuntor é a única unidade capaz de lidar com múltiplas descargas e correntes de falha evolutivas.

Redução de trabalho de manutenção

O uso de interrompedores a vácuo nas seções de interrupção de corrente elimina a necessidade de inspeção dessas seções. Portanto, horas-homem podem ser economizadas para manutenção e inspeção.

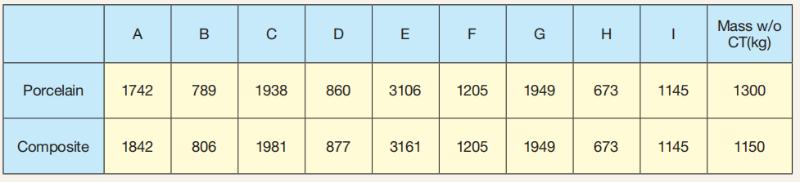

Tipo e Especificações

Especificações

Tensão nominal (kV) |

36 |

72.5 |

|

Tensão de resistência |

1 min frequência de rede (kV eficaz) |

70 |

140 |

Impulso 1.2x50μs (kV pico) |

200 |

350 |

|

Frequência nominal (Hz) |

50/60 |

||

Corrente nominal (A) |

2000 |

2000/3150 |

|

Corrente de curto-circuito nominal do disjuntor (kA) |

31.5 |

40 |

|

Tensão de recuperação transitória nominal |

Taxa de subida (kV/μs) |

1.19 |

1.47 |

Fator do primeiro polo a desligar |

1.5 |

||

Corrente de fechamento em curto-circuito nominal (kA) |

82 |

104 |

|

Corrente de tempo curto nominal (kA) |

31.5 (3s) |

40 (3s) |

|

Tempo de interrupção nominal (ciclos) |

3 |

||

Tempo de abertura nominal (s) |

0.033 |

0.03 |

|

Tempo de fechamento sem carga (s) |

0.05 |

0.10 |

|

Ciclo de operação |

O-0.3s-CO-15s-CO |

||

Tensão de comando de fechamento (Vdc) |

48, 100, 110, 125, 250 |

||

Tensão de comando de desligamento nominal (Vdc) |

48, 100, 110, 125, 250 |

||

Tensão de alimentação para motor de carregamento |

(Vdc) |

48, 100, 110, 125, 250 |

|

(Vac) |

60, 120, 240 |

||

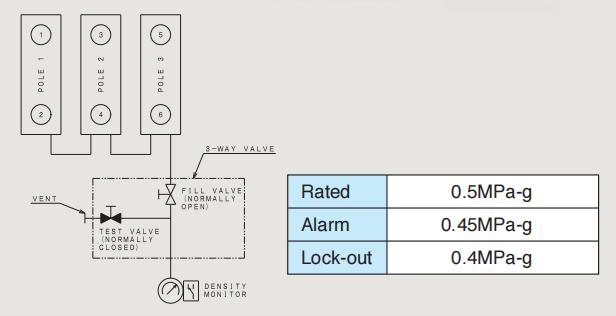

Pressão nominal de ar seco |

0.5MPa-g (a 20℃ ) |

||

Sistema de operação de fechamento |

Mola |

||

Sistema de controle de desligamento |

Mola |

||

Padrão aplicável |

IEC 62271-100-2008, ANSI/IEEE C37.06-2009 |

||

Construção

Construção geral

Para cada fase, um interrompedor de vácuo para quebra de corrente é acomodado no tanque aterrado. O sistema de operação é tal que o fechamento e a abertura são realizados por força de mola. O mecanismo de operação e a interligação trifásica são montados em uma base comum, que é instalada nas pernas do quadro.

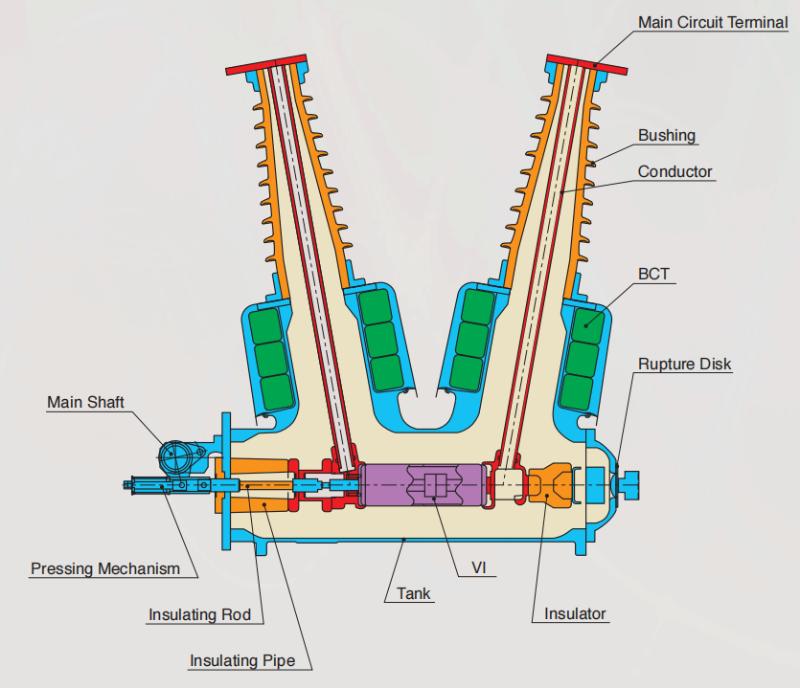

Construção interna

A estrutura geral é composta principalmente pelo tanque aterrado, interrompedores de vácuo (IV), varas isolantes, bushings e terminais de circuito principal. Cada tanque aterrado é preenchido com ar seco mantido sob pressão nominal de 0,5 MPa-g (20℃).

Construção interna do disjuntor de vácuo

Sistema de ar seco

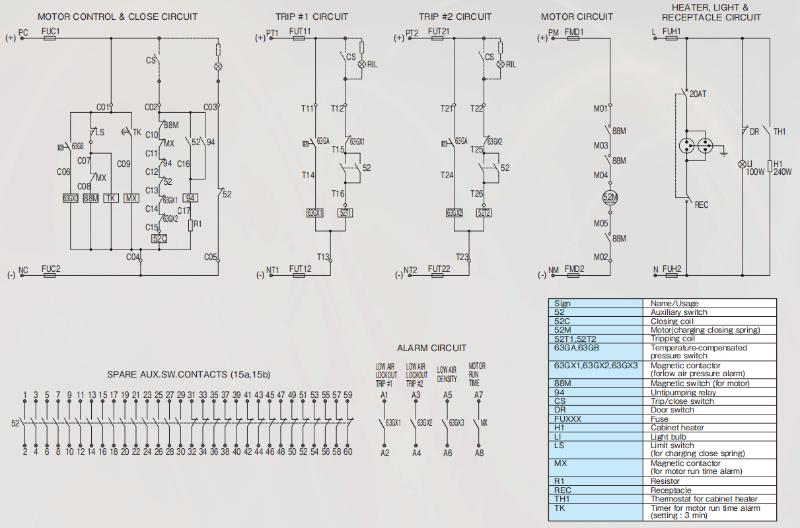

Desenho de esquema

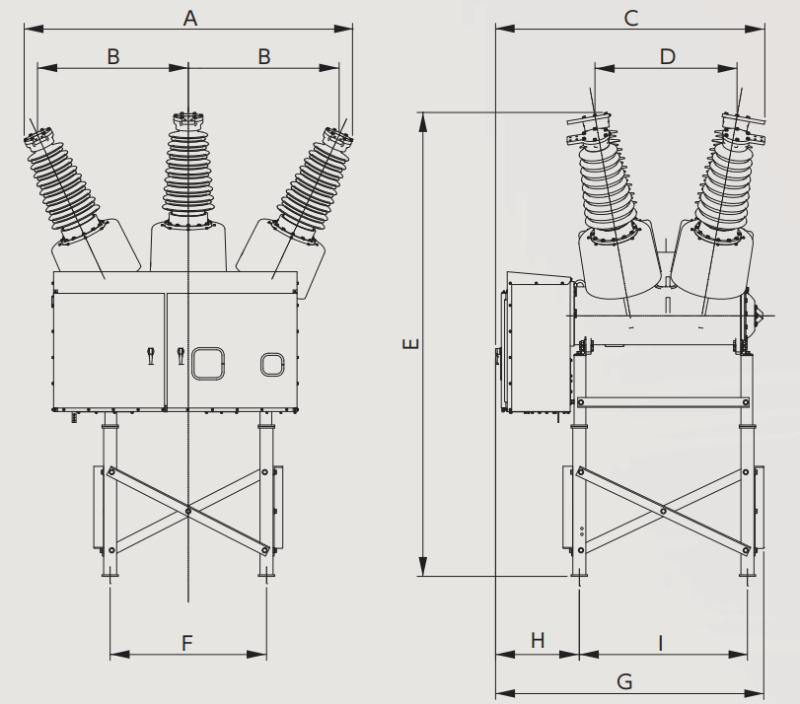

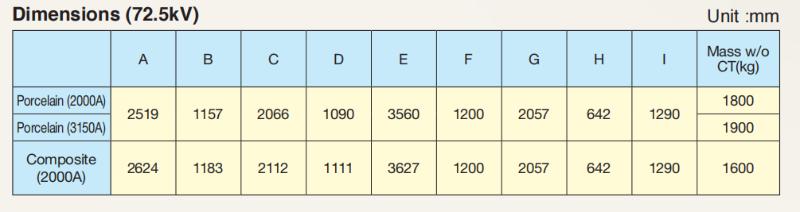

Dimensões (72,5 kV)

Dimensões (36 kV)

Diagrama de conexão padrão

Desempenho

O desempenho do disjuntor foi projetado de acordo com os padrões ANSI e IEC e verificado através de testes de tipo. Todos os produtos são enviados após a confirmação de vários desempenhos por meio de testes de aceitação baseados nesses padrões.

Características de resistência à tensão : O desempenho de resistência à tensão está assegurado na pressão especificada de ar seco. Mesmo que a pressão de ar seco tenha sido reduzida para o nível de alarme, o nível de isolamento necessário pode ser assegurado. Além disso, mesmo que esta pressão seja reduzida para a pressão atmosférica, o disjuntor resiste à tensão nominal.

Desempenho de passagem de corrente : Como os contatos principais estão localizados sob vácuo, suas superfícies nunca são oxidadas e, portanto, o desempenho de passagem de corrente é estabilizado. No modo de fechamento do disjuntor, uma força de compressão é exercida entre os contatos principais pelo efeito da mola de compressão, assegurando tolerância suficiente contra a corrente de fechamento e a corrente de curto prazo.

Vida útil mecânica : Devido à adoção de um mecanismo de operação simplificado, as características de comutação são extremamente estabilizadas. O desempenho de comutação frequente também foi verificado através de testes de comutação mecânicos contínuos, repetindo as operações de comutação mais de 10.000 vezes.

Vida útil elétrica : Como a interrupção de corrente é realizada no interrompedor de vácuo, a energia gerada durante a interrupção de corrente é extremamente baixa e a erosão dos contatos é mínima. Isso implica em longa vida útil dos contatos. Comutação de corrente de carga: 10.000 vezes

Comutação de corrente nominal de interrupção: 20 vezes

Estrutura do Tanque Integral:

-

Estrutura do Tanque Integral: A câmara de extinção de arco, o meio isolante e os componentes relacionados estão selados dentro de um tanque metálico preenchido com gás isolante (como hexafluoreto de enxofre) ou óleo isolante. Isso forma um espaço relativamente independente e selado, efetivamente impedindo que fatores ambientais externos afetem os componentes internos. Este design aumenta o desempenho de isolamento e a confiabilidade do equipamento, tornando-o adequado para vários ambientes externos adversos.

Disposição da Câmara de Extinção de Arco:

-

Disposição da Câmara de Extinção de Arco: A câmara de extinção de arco geralmente é instalada dentro do tanque. Sua estrutura é projetada para ser compacta, permitindo uma extinção de arco eficiente em um espaço limitado. Dependendo dos diferentes princípios e tecnologias de extinção de arco, a construção específica da câmara de extinção de arco pode variar, mas geralmente inclui componentes-chave como contatos, bocais e materiais isolantes. Esses componentes trabalham juntos para garantir que o arco seja rapidamente e efetivamente extinto quando o disjuntor interrompe a corrente.

Mecanismo de Operação:

-

Mecanismo de Operação: Mecanismos de operação comuns incluem mecanismos acionados por mola e mecanismos acionados hidraulicamente.

-

Mecanismo Acionado por Mola: Este tipo de mecanismo tem uma estrutura simples, é altamente confiável e fácil de manter. Ele impulsiona as operações de abertura e fechamento do disjuntor através do armazenamento e liberação de energia das molas.

-

Mecanismo Acionado Hidraulicamente: Este mecanismo oferece vantagens como alta potência de saída e operação suave, tornando-o adequado para disjuntores de classe de alta tensão e alta corrente.